- carbon crystal panel

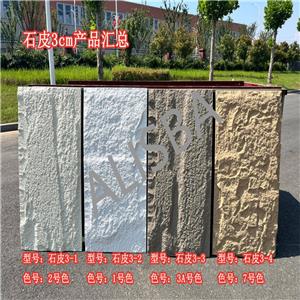

- artificial stone

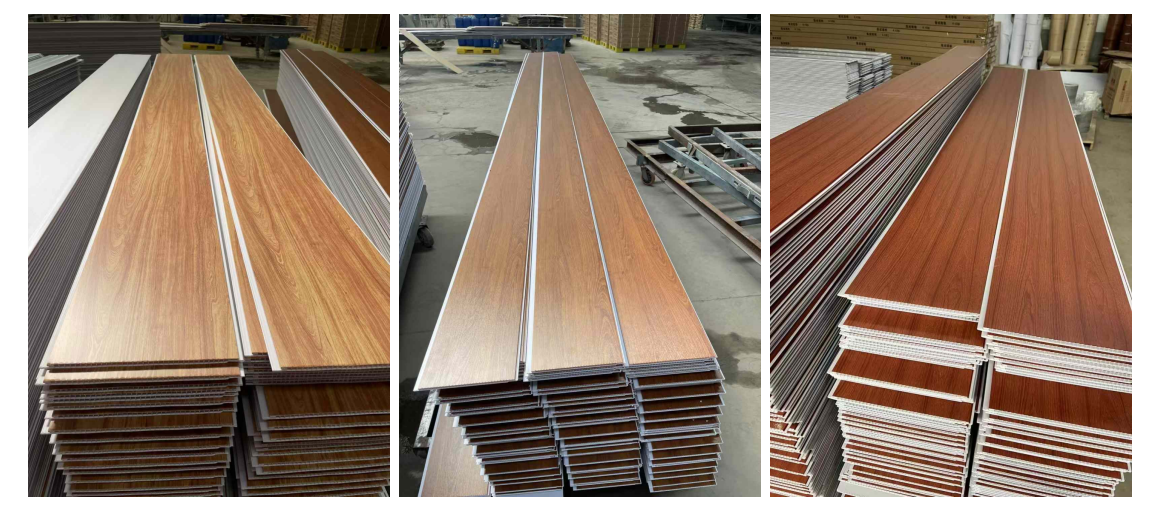

- Stone plastic wall panel

- Fish Bone Laminate Flooring

- self-adhesion wall sticker

- herringbone Floor

- High customer satisfaction: High quality products win praise

- About rhe SPC Flooring

- About Soft Stone Products

- Have a good news

- News from wall panels

- Industry news

How to determine whether the quality of PVC ceiling is qualified

Evaluating the quality of PVC ceiling is a key step in ensuring the purchase of cost-effective building materials. Here are several main aspects to help you check whether the PVC ceiling meets the qualified standards:

Appearance inspection:

Observing color uniformity, high-quality PVC ceiling should have consistent colors without color differences or spots.

Check the surface smoothness, there should be no obvious unevenness, cracks or defects.

Check the edges, high-quality products have smooth and neat edges without burrs.

Thickness and dimensional accuracy:

Measure the actual thickness with a caliper and compare it with the sales specifications. The deviation should be within ± 0.2mm.

Confirm whether the length and width meet the order requirements, with an allowable error range of ± 1%.

Bending toughness test:

Gently try bending a sample, high-quality PVC ceiling should have good toughness and memory, and be able to recover to its original state without obvious creases or fractures after bending.

Fire rating verification:

Conduct combustion testing according to international standards such as ISO 4589 or ASTM E84 to confirm whether its flame retardancy meets the standard.

It is possible to observe the ash condition after combustion. High quality PVC burns slowly and does not produce a large amount of smoke or toxic gases.

Waterproof performance testing:

Soak the sample in water for 24 hours and check for obvious deformation or water absorption. High quality PVC ceiling should maintain dimensional stability.

Sound tapping test:

Lightly tapping the buckle, high-quality materials will produce a crisp and loud sound instead of a dull sound, indicating a high degree of internal density.

View certification and reports:

Confirm if the supplier can provide relevant quality certificates such as CE, RoHS, SGS, as well as testing reports issued by third-party laboratories.

Understand the source of raw materials:

Inquire about the quality of PVC resin used in production, and prioritize products made from brand new materials to avoid potential issues caused by recycled materials.

Through the above steps, combined with the needs of practical application scenarios, you can comprehensively evaluate the quality of PVC ceiling and make wise purchasing decisions. For large-scale procurement, it is recommended to negotiate with suppliers for batch sampling inspection to ensure that each batch of products meets high standards